SC Rewinds Ltd. Servicing

Precision Motor Repair Backed by Advanced Technology

🏭 Heavy-Duty Capability & Expert Diagnostics

At SC Rewinds, our fully equipped workshop can accommodate motors up to 8 tons, enabling us to tackle even the most demanding repair and rewind projects. We service all types of AC/DC motors using state-of-the-art diagnostic tools to ensure accuracy and reliability.

Cutting-Edge Testing Equipment

- Electrom iTIG IV Surge Tester This fully automated system detects even the smallest shorts or ground faults. It stores results to iCloud or USB, making it ideal for periodic inspections and long-term monitoring.

- Digital Baker Surge Tester Used as a backup or for on-site diagnostics, this tool is essential for identifying faults and providing clear, actionable insights to our customers.

- Phenix Core Tester Highlights lamination core and rotor faults, pinpointing hot spots that can compromise motor efficiency. Identifying and correcting these issues ensures longer-lasting repairs and optimal performance.

Precision Repair & Rewind Techniques

- Pyrolysis Oven Utilised for stripping windings from large motors, this water jet temperature-controlled system protects laminations from overheating during the process.

Samatic Coil Winding Machine Produces smooth, kink-free coils for easier insertion, balanced winding, and superior slot fill—critical for motor efficiency and durability.

Class H Water-Based Epoxy Varnish Offers deeper penetration, enhanced resistance to chemical attack, and improved vibration tolerance compared to solvent-based alternatives

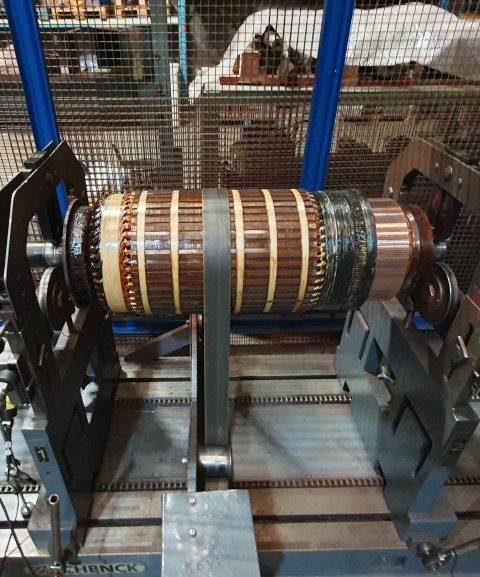

Schenck Rotor Balancing Machine Capable of handling rotors up to 3 tons, this ensures precise balancing to extend bearing life and reduce vibration—just like balancing wheels on a car.

SC Rewinds Servicing